Item No :

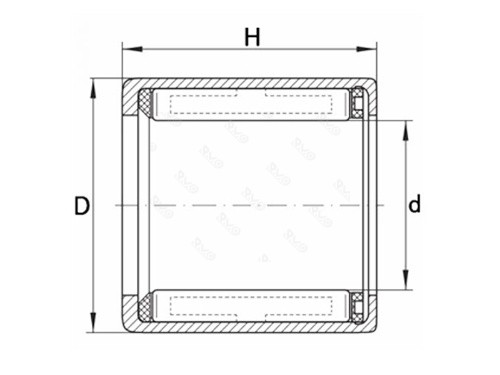

HF1216Size (d*D*B) :

12x18x16mmMaterial :

ST14 steel with chrome steel GCr15Lead Time :

3-5 daysWeight :

0.011KGPayment Terms :

100% T/T or 30% T/T before production, 70% before deliveryPackage :

plastic bag, plastic tube or single box+Carton+PalletShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

100 PCSCompact HF1216 One-way Drawn Cup Needle Roller Bearing

⚙️Product description:

In some industrial setups, especially where space is limited and directional rotation matters, a one-way drawn cup needle roller bearing might be the right fit. It’s often referred to as a needle clutch and is built using a stamped outer shell. Inside, there’s a set of rollers—these are kept in place by a cage, which could use either a plastic or stainless steel spring depending on the application.

This type of one-way drawn cup needle roller bearing has grooves on the outside, which makes it especially useful in making diabolo toys. Some manufacturers in the fitness equipment sector prefer a version with a solid ring. There's even an ultra-thin design developed to accommodate the needs of companies working on delicate, high-precision machinery.

High load and wear resistance: Adopting alloy steel stamping outer ring and bevelled design, the special heat treatment significantly improves wear resistance and load capacity, suitable for high load scenarios.

Compact structure: Thin-walled outer ring design saves radial space, and the combination of plastic cage and metal spring ensures low free rotating friction torque, which is suitable for precision transmission system.

Reliable unidirectional locking: Unidirectional transmission is achieved by mechanical locking of the needle rollers to the bevelled surfaces, making them suitable for anti-reversing, indexing or clutch applications, stable operation and low maintenance requirements.

| Model No. | d | D | H | m |

| HF0612 | 6 mm | 10 mm | 12 mm | 3 g |

| HF0812 | 8 mm | 12 mm | 12 mm | 3.5 g |

| HF1012 | 10 mm | 14 mm | 12 mm | 4 g |

| HF1216 | 12 mm | 18 mm | 16 mm | 11 g |

| HF1416 | 14 mm | 20 mm | 16 mm | 13 g |

| HF1616 | 16 mm | 22 mm | 16 mm | 14 g |

| HF1816 | 18 mm | 24 mm | 16 mm | 16 g |

| HF2016 | 20 mm | 26 mm | 16 mm | 17 g |

| HF2520 | 25 mm | 32 mm | 20 mm | 30 g |

| HF3020 | 30 mm | 37 mm | 20 mm | 36 g |

| HF3520 | 35 mm | 42 mm | 20 mm | 40 g |

Engineering machinery and transmission systems: Due to its compact structure and high load capacity, it is commonly used in mechanical equipment requiring unidirectional transmission, such as gear pumps, clutch devices and power transmission mechanisms.

Power tools and small equipment: Suitable for space-constrained scenarios, such as power tools, automation equipment transmission components, to provide stable high-speed performance.

Bicycles and two-wheeled electric vehicles: Some models can be adapted to the drive system of two-wheeled electric vehicles, supporting the demand for high-precision, low-noise unidirectional motion.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on