Item No :

PHS10 PHS10L rod end bearingSize (d*D*B) :

10x26x56x14mmMaterial :

steel with zinc platedLead Time :

normally 3-5 daysWeight :

0.07KGMOQ :

50 PCSFisheye Bearing PHS10 Female Thread Rod End Bearing

⚙️Product Description:

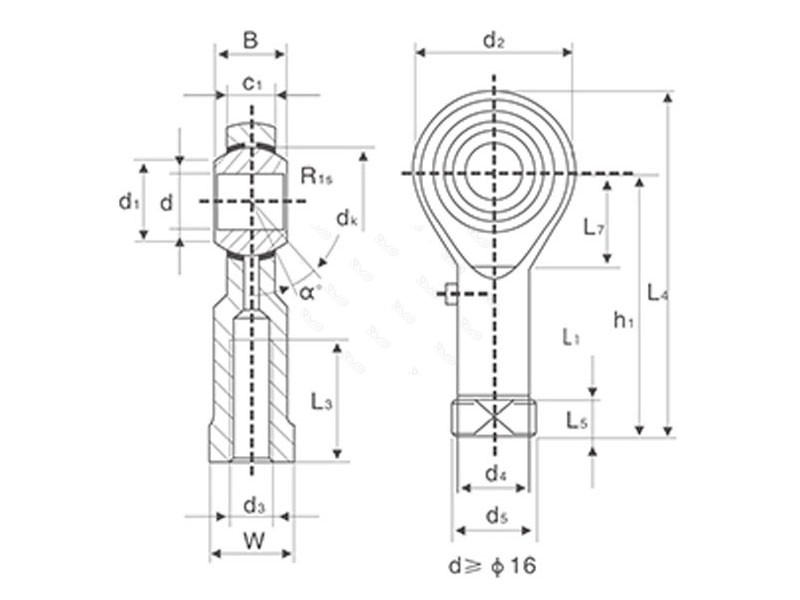

The PHS10 internal thread type rod-end joint bearing is a type of spherical sliding bearing, commonly known as "fish-eye bearing". The thread specification is usually M10×1.5. The thread direction of PHS10 is right-handed, while that of PHS10L is left-handed. Its core function is to achieve force transmission and angle compensation between two components in low-speed motion scenarios. Even if there is a significant concentricity deviation between the supporting shaft and the shaft housing hole, it can still maintain stable operation.

Main structure: The basic structure is composed of the "outer ring with inner spherical surface (bearing housing)" and the "inner ring with outer spherical surface (ball head)", with special material pads embedded between them.

| Product name | PHS10 PHS10L rod end bearing |

| Size | 10x26x56x14mm |

| Material | steel with zinc plated |

| Weight | 0.07KG |

| lead time | normally 3-5 days |

| Package | Single box +Carton +Pallet |

| MOQ | 50 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

⚙️Bearing material:

Bearing housing (Holder): Made of carbon steel, treated with colored chromate, featuring high strength and corrosion resistance;

Ball head inner ring: Utilizes bearing steel, with a surface hardness of over 58HRC, and the spherical area is electroplated with hard chromium and polished to mirror-like precision;

Intermediate spacer: For some models, it is embedded with a special copper alloy with high adhesion or self-lubricating synthetic resin to achieve low-friction movement.

Functional accessory: The bearing housing is equipped with an oil nipple. Lubricating grease can be replenished as needed. Some models are pre-filled with light oil and can be used directly upon factory delivery.

⚙️Performance Advantages:

High precision movement: The sliding surface gap is extremely small, enabling seamless and ultra-smooth rotational and oscillating movements;

Load capacity: It can withstand radial, axial, and combined loads. The basic rated dynamic load is approximately 9810N, and the basic rated static load is approximately 13300N.

Environmental resistance: The chromate coating ensures superior corrosion resistance compared to ordinary stainless steel models, with the working temperature range covering -20℃ to 80℃;

Angle compensation: It allows for a certain inclination angle, typically 8°, which can effectively counteract the impact of installation misalignment.

| Model No. | Main Dimension(mm) | Load (KN) | weight (g) | ||||||||||||||

| D | D3 | B | C1 | W | L3min | D2 | L4 | h1 | L5 | D4 | D5 | DK | D1 | Dyn.C | Stat.C0 | ||

| PHS 5 | 5 | M5*0.8 | 8 | 6 | 9 | 10 | 16 | 35 | 27 | 4 | 8.5 | 11 | 11.11 | 7.7 | 3.25 | 5.7 | 15.2 |

| PHS 6 | 6 | M6*1.0 | 9 | 6.75 | 11 | 12 | 18 | 39 | 30 | 5 | 10 | 13 | 12.7 | 8.96 | 4.3 | 7.2 | 22.3 |

| PHS 8 | 8 | M8*1.25 | 12 | 9 | 14 | 16 | 22 | 47 | 36 | 5 | 12.5 | 16 | 15.875 | 10.4 | 7.2 | 11.6 | 42.2 |

| PHS10 | 10 | M10*1.5 | 14 | 10.5 | 17 | 20 | 26 | 56 | 43 | 6.5 | 15 | 19 | 19.05 | 12.9 | 10 | 14.5 | 68.6 |

| PHS10-1 | 10 | M10'1.25 | 14 | 10.5 | 17 | 20 | 26 | 56 | 43 | 6.5 | 15 | 19 | 19.05 | 12.9 | 10 | 14.5 | 68.6 |

| PHS12 | 12 | M12*1.75 | 16 | 12 | 19 | 22 | 30 | 65 | 50 | 6.5 | 17.5 | 22 | 22.225 | 15.4 | 13.4 | 17 | 104 |

| PHS12-1 | 12 | M12-1.25 | 16 | 12 | 19 | 22 | 30 | 65 | 50 | 6.5 | 17.5 | 22 | 22.225 | 15.4 | 13.4 | 17 | 104 |

| PHS14 | 14 | M14*2.0 | 19 | 13.5 | 22 | 25 | 34 | 74 | 57 | 8 | 20 | 25 | 25.4 | 16.9 | 17 | 24 | 143.5 |

| PHS14-1 | 14 | M14*1.5 | 19 | 13.5 | 22 | 25 | 34 | 74 | 57 | 8 | 20 | 25 | 25.4 | 16.9 | 17 | 24 | 143.5 |

| PHS16 | 16 | M16*2.0 | 21 | 15 | 24 | 28 | 38 | 83 | 64 | 8 | 22 | 27 | 28.575 | 19.4 | 21.6 | 28.5 | 197.5 |

| PHS16-1 | 16 | M16*1.5 | 21 | 15 | 24 | 28 | 38 | 83 | 64 | 8 | 22 | 27 | 28.575 | 19.4 | 21.6 | 28.5 | 197.5 |

Widely used in mechanical arms, packaging machinery, conveying systems, printing machines, textile equipment, automotive steering systems, suspension systems, material handling equipment, fitness equipment, construction equipment, etc., in all occasions where motion and force need to be transmitted.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on