Item No :

30306Size (d*D*B) :

30x72x20.75mmMaterial :

chrome steel (GCr15)Brand :

famous brand/RMO/Neutral/OEMLead Time :

3-5 daysWeight :

0.445KGService :

OEM/ODMFrictionless Pure Rolling 30306 Tapered Roller Bearings

⚙️Product description:

Single row tapered roller bearings are designed with detachable inner and outer rings, each featuring a conical raceway. Thanks to this structure, the single row tapered roller bearing are especially suited to manage both radial loads and one-directional axial loads. The rollers themselves are also tapered, and their shape is carefully calculated—when projected, the tapered lines of the roller surfaces meet at a single point along the bearing axis. This clever geometric alignment helps the rollers roll smoothly along the raceways with minimal sliding, enhancing both performance and longevity.

Single row tapered roller bearings are constructed so that the inner assembly—including rollers, cage, and inner ring—can be detached from the outer ring. This separable design makes it easier to handle shaft and housing installation, while also allowing independent mounting of the inner and outer components. As a result, both radial and axial clearances can be adjusted with precision.

Depending on the number of roller rows, single row tapered roller bearings are available in single-row, double-row, and four-row configurations. Single-row types are mainly used to carry axial loads in one direction and are often paired to counteract internal axial forces. Bearings with two or four rows are capable of managing radial loads along with axial loads in both directions, making them ideal for demanding applications where load capacity is a key consideration.

Single row tapered roller bearing size range:

Inner diameter range: 20mm ~ 1270mm

Outer diameter range: 40mm ~ 1465mm

Width range: 15mm ~ 240mm

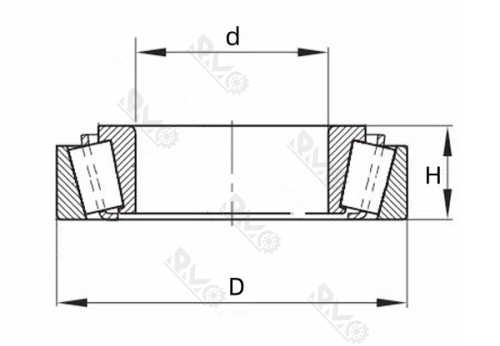

| Model No. | d | D | H | m |

| 30302 | 15 mm | 42 mm | 14.25 mm | 0.1 KG |

| 30303 | 17 mm | 47 mm | 15.25 mm | 0.13 KG |

| 30304 | 20 mm | 52 mm | 16.25 mm | 0.19 KG |

| 30305 | 25 mm | 62 mm | 18.25 mm | 0.27 KG |

| 30306 | 30 mm | 72 mm | 20.75 mm | 0.45 KG |

| 30307 | 35 mm | 80 mm | 22.75 mm | 0.57 KG |

| 30308 | 40 mm | 90 mm | 25.25 mm | 0.81 KG |

| 30309 | 45 mm | 100 mm | 27.25 mm | 1 KG |

| 30310 | 50 mm | 110 mm | 29.25 mm | 1.38 KG |

| 30311 | 55 mm | 120 mm | 31.5 mm | 1.8 KG |

| 30312 | 60 mm | 130 mm | 33.5 mm | 2.02 KG |

| 30313 | 65 mm | 140 mm | 36 mm | 2.4 KG |

| 30314 | 70 mm | 150 mm | 38 mm | 3.02 KG |

| 30315 | 75 mm | 160 mm | 40 mm | 3.64 KG |

| 30316 | 80 mm | 170 mm | 42.5 mm | 4.34 KG |

| 30317 | 85 mm | 180 mm | 44.5 mm | 4.83 KG |

| 30318 | 90 mm | 190 mm | 46.5 mm | 5.83 KG |

| 30319 | 95 mm | 200 mm | 49.5 mm | 6.77 KG |

| 30320 | 100 mm | 215 mm | 51.5 mm | 8.3 KG |

| 30321 | 105 mm | 225 mm | 53.5 mm | 9.54 KG |

| 30322 | 110 mm | 240 mm | 54.5 mm | 11 KG |

| 30324 | 120 mm | 260 mm | 59.5 mm | 14.3 KG |

| 30326 | 130 mm | 280 mm | 63.75 mm | 17.1 KG |

| 30328 | 140 mm | 300 mm | 67.75 mm | 20.4 KG |

Tapered roller bearings are commonly applied in situations requiring support for radial loads, axial forces in a single direction, or a combination of both. Their design makes them especially reliable in industries such as automotive, mining, metallurgy, plastics, and machinery manufacturing. Typical applications include vehicle drivetrains, mining equipment, and the working components of rolling mills. Thanks to their durability and load-handling capacity, these bearings are often the preferred choice in demanding environments and heavy-duty operations.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on