Item No :

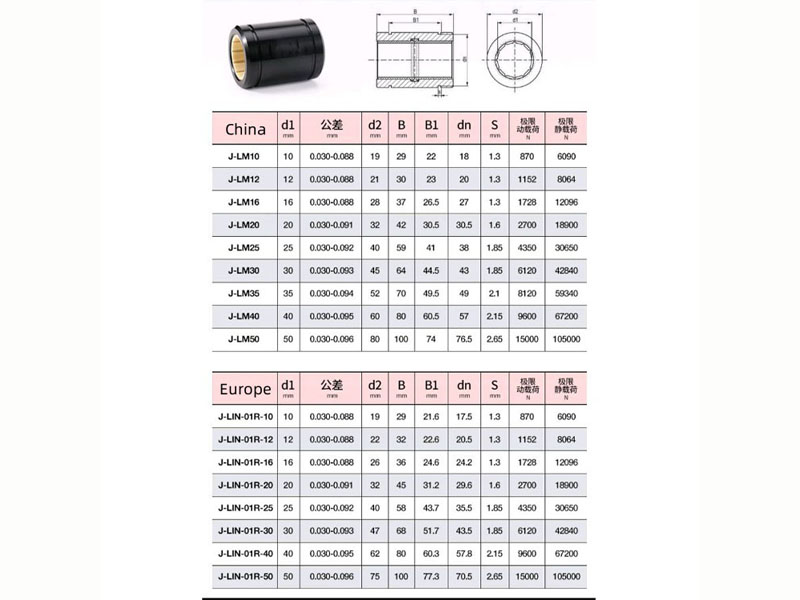

RJUM-01-10 J-LIN-01R-10Size (d*D*B) :

10x19x29mmMaterial :

Aluminum alloy + plastic + flexible fiberLead Time :

Normally 3-5 daysWeight :

0.014KGShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

50 pcsHigh-load RJUM-01-10 J-LIN-01R-10 Plastic Linear Bearing

⚙️Product description:

RJUM-01-10 Plastic linear bearings are a type of linear motion system with self-lubrication properties. They belong to the surface-contact sliding friction type of bearings and are suitable for high-load, medium-low speed motion scenarios.

Working principle: The plastic linear bearing operates through sliding friction, with the bearing in contact with the cylindrical shaft in a surface manner, making it suitable for high-load, medium-speed movements. In contrast, the metal linear bearing utilizes rolling friction, with the bearing in contact with the cylindrical shaft at points. It is suitable for low-load, high-speed movements.

Structure and materials: The plastic linear bearing is typically composed of an aluminum alloy outer casing and an internal sliding film. The outer casing is made of aluminum alloy 6061T6. The internal sliding film is made by adding reinforcing fibers, fillers, and solid lubricants to the base material to achieve self-lubrication and low friction performance.

⚙️Performance features:

Self-lubrication: The internal sliding film contains self-lubricating components, eliminating the need for additional lubricants, which can reduce maintenance costs and is suitable for situations where lubrication is difficult or has specific requirements.

Low noise: The movement is quiet, especially at medium and high speeds, and the noise is less affected by speed changes, making it suitable for environments sensitive to noise.

Corrosion resistance: The plastic material has good corrosion resistance and can operate in humid and chemical corrosive medium environments, without rusting or corrosion.

Dust prevention and self-cleaning: Usually, there is a chip removal groove design inside, allowing it to be used in dusty environments. Dust can be automatically removed from the chip removal groove during movement.

Light weight: Compared to metal linear bearings, plastic linear bearings are lighter in weight, which helps in the lightweight design of equipment.

⚙️Product Application:

It is widely used in industrial fields such as precision machine tools, textile machinery, and food packaging machinery, and is particularly suitable for scenarios with high load, medium to low speed, corrosion resistance requirements, or low noise.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on