LM11949/LM11910 single row tapered roller bearings have the core advantage of being able to withstand combined radial and axial loads.

Item No :

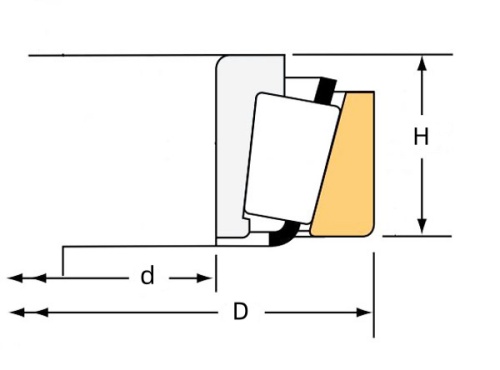

LM11949/LM11910 (LM11949/10)Size (d*D*B) :

19.05x45.24x15.49mmMaterial :

chrome steel (GCr15)Lead Time :

3-5 daysWeight :

0.12KGMOQ :

50 pcsHigh Precision LM11949/LM11910 Inch Tapered Roller Bearing for Precision Engineering

⚙️Core structure and material:

Reference Load: The basic rated dynamic load is approximately 31.5 KN, and the basic rated static load is approximately 28.5 KN.

Reference rotational speed: The limit rotational speed for grease lubrication is 9000 r/min, and for oil lubrication it is 12000 r/min.

⚙️Core advantages:

1) Separable structure (cone and cup can be installed independently) enables convenient assembly and inspection.

2) Capable of withstanding combined radial and axial loads, suitable for medium - load working conditions.

3) Equipped with a stamped steel cage, it ensures stable operation with low friction and low heat generation during high - speed rotation.

| Model No. | sizes(mm) | KGS |

| LM11749/LM11710 | 17.46x39.88x13.84 | 0.09 |

| LM11949/LM11910 | 19.05x45.24x15.49 | 0.12 |

| LM48548/LM48510 | 34.92x65.09x18.03 | 0.25 |

| HM218248/HM218210 | 89.97x146.97x40 | 2.52 |

| LM104949/LM104911 | 50.8x82.55x21.59 | 0.42 |

| LM67048/LM67010 | 31.75x59.131x15.88 | 0.18 |

| LM102949/102910 | 45.24x73.431x19.56 | 0.31 |

| LM603049/LM603011 | 45.24x77.79x19.84 | 0.37 |

| HM212049/HM212010 | 66.68x122.24x38.1 | 1.85 |

| L44643/L44610 | 25.4x50.29x14.22 | 0.13 |

| LM501349/LM501310 | 41.28x73.43x19.56 | 0.34 |

| 25580/25520 | 44.45x82.93x23.81 | 0.56 |

| L68149/L68110 | 34.99x59.13x15.88 | 0.17 |

| L44649/L44610 | 26.99x50.29x14.22 | 0.12 |

It is widely used in front axles, differentials, and pinion assemblies of automobiles, tractors, and trailers. Besides, it fits conveyor rolls, machine tool spindles, metallurgical equipment, and mining machinery. It also matches OEM parts of brands like John Deere, Mercedes - Benz, and AGCO.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on