Item No :

KFL006Size (d*D*B) :

30x112x70x85x27mmMaterial :

chromel steel+zinc alloyBrand :

famous brand/RMO/Neutral/OEMLead Time :

3-5 daysWeight :

0.22KGShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

10pcsKFL006 Flange Zinc Alloy Pillow Block Bearing

⚙️Product description:

High thermal conductivity pillow block bearings are a practical alternative to copper parts, offering solid durability and resistance to wear. They work well with lubricants and, in many cases, even reduce the need for extra lubrication thanks to their self-lubricating nature. These high thermal conductivity pillow block bearings don’t easily bond with steel shafts because of their low melting point, which also makes them less prone to wear from friction. In real-world use, they often outlast copper bushings—sometimes by more than double—helping lower maintenance costs. They also shed heat quickly, keeping operating temperatures under control and protecting nearby components. Weighing much less than copper parts, they're easier to handle and install. Plus, their ability to dampen vibration means quieter, smoother operation.

1. Longevity: 2x longer lifespan than copper alloys under similar conditions, lowering replacement costs.

2. Cost-Effectiveness: Combines lightweight design with reduced material expenses.

3. Strength & Durability: Comparable to aluminum bronze in strength, hardness, and pressure resistance, surpassing tin and lead alloys.

4. Speed Capability: Matches aluminum bronze in allowable speed, making it suitable for high-speed applications like independent anti-friction bearing shells.

5. Lubrication & Friction Management

· Oil Affinity: Strong adhesion to lubricants, enabling superior self-lubrication.

· Anti-Wear Properties: Metallurgical stability (low melting point, non-reactive with steel shafts) prevents adhesion and friction wear.

6. Thermal Efficiency

· High Thermal Conductivity:

ZZnAl27Cu2Mg: λ = 125 W/m·K (rapid heat dissipation).

ZCuAl10Fe3: λ = 59 W/m·K.

· Temperature Control: Slows surface temperature rise, protecting paired friction components.

· Low Density: ZZnAl27Cu2Mg (ρ = 5 g/cm³) reduces product weight by ~66% compared to copper alloys, easing installation and maintenance.

7. Vibration & Noise Reduction

· Damping Characteristics: High inherent damping absorbs vibrations, minimizing noise in dynamic systems.

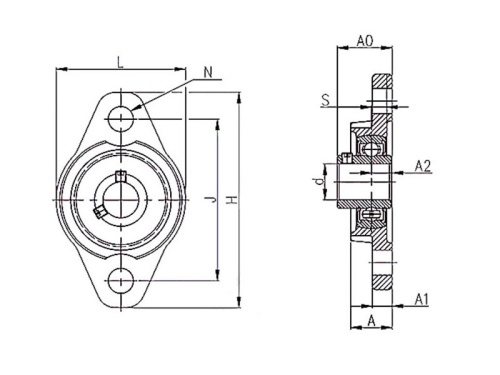

| Model No. | ID(mm) | Dimensions(mm) | |||||||||

| diamond-type | d | H | L | A | J | N | A1 | A2 | A0 | S | KG |

| KFL08 | 8 | 48 | 27 | 8.5 | 36 | 5 | 4 | 4 | 12 | 3 | 0.022 |

| KFL000 | 10 | 60 | 36 | 11.5 | 45 | / | 5.5 | 5.5 | 15.5 | 4 | 0.0358 |

| KFL001 | 12 | 63 | 38 | 11.5 | 48 | 7 | 5.5 | 5.5 | 16 | 4 | 0.0415 |

| KFL002 | 15 | 67 | 42 | 13 | 53 | 7 | 6.5 | 6.5 | 18.5 | 4.5 | 0.0552 |

| KFL003 | 17 | 71 | 46 | 14 | 56 | 7 | 7 | / | 19.5 | 5 | 0.0715 |

| KFL004 | 20 | 90 | 55 | 16 | 71 | 10 | 8 | 8 | 23 | 6 | 0.1217 |

| KFL005 | 25 | 95 | 60 | 16 | 75 | 10 | 8 | 8 | 24.5 | 6 | 0.145 |

| KFL006 | 30 | 112 | 70 | 18 | 85 | 13 | 9 | 9 | 27 | 6.5 | 0.22 |

· Critical Components: Engine crankshafts, transmissions, and steering systems rely on zinc alloy bearings for reliability and safety.

· Motor Applications: Essential in electric motors, generators, and gearboxes for smooth operation under continuous loads.

· Agricultural Machinery

Harsh Conditions: Used in rice transplanters and harvesters to withstand heavy loads and reduce friction in outdoor environments.

· Construction Machinery

Heavy-Duty Use: Excavators and bulldozers utilize zinc alloy bearings for corrosion resistance, high-temperature tolerance, and durability.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on