Item No :

NHS8T NHS8TL rod end bearingSize (d*D*B) :

8x47x22x12mmMaterial :

steel with zinc platedLead Time :

normally 3-5 daysWeight :

0.043KGMOQ :

100 PCSNHS8T Female Thread Self-lubricating Rod-end Joint Bearing

⚙️Product Structure:

Spherical Inner Ring (Ball): Made of bearing steel SUJ2, the surface is precisely processed to achieve bearing-level hardness and precision, ensuring sliding stability;

Rod End Body: Selected from S35C chrome-plated steel (some models are S20C), it combines rust prevention and structural strength, and the internal thread design enables quick assembly;

Self-lubricating Gasket: Self-lubricating synthetic resin is embedded between the steel cage and the spherical inner ring, forming a gap-free sliding interface, minimizing motion errors.

Connection Characteristics: Uses M8 specification internal thread (pitch 1.25mm), default right-hand direction (left-hand can be customized as NHS8TL model), compatible with corresponding specification threaded connection components.

| Product name | NHS8T NHS8TL rod end bearing |

| Size | 8x47x22x12mm |

| Material | steel with zinc plated |

| Weight | 0.043KG |

| lead time | normally 3-5 days |

| Package | Single box +Carton +Pallet |

| MOQ | 100 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

Maintenance-free: The self-lubricating resin gasket requires no oil replenishment throughout its service life, reducing equipment maintenance costs and downtime;

High-precision motion: The sliding surface gap is extremely small, enabling gapless swinging and linkage, ensuring mechanical operation accuracy;

Anti-contamination: There is no risk of oil leakage, suitable for sensitive scenarios such as food machinery and clean equipment;

Corrosion resistance: The main body is chrome-plated and the SUJ2 spherical material enhances rust prevention, extending service life.

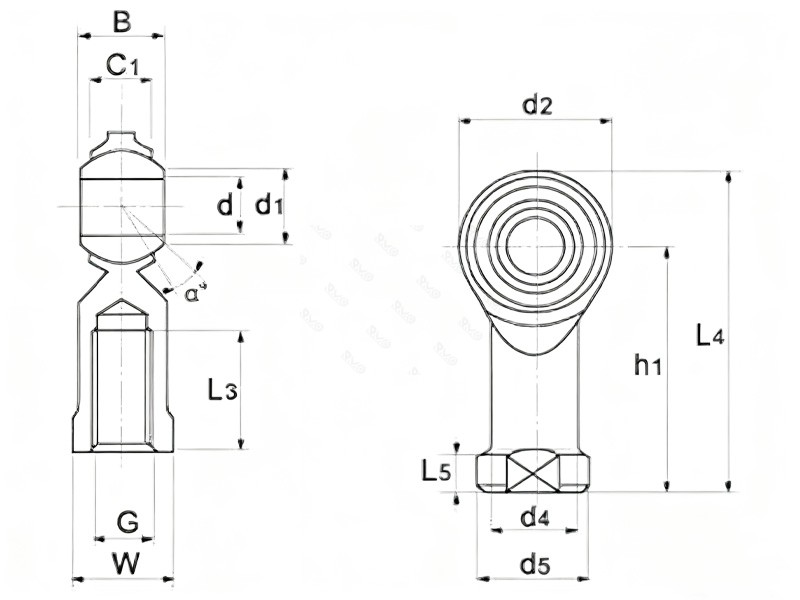

| Model No. | d | d1 | B | a | C1 | d2 | G | h1 | L4 | L3 | d4 | ds | Ls | W | Rotational torque(kgf-cm) | Load ratings(kgf)/static | Weight(g) |

| NHS 3 | 3 | 6.8 | 6 | 11 | 4.5 | 12 | M3x0.5 | 21 | 27 | 10 | 6.5 | 8 | 3 | 7 | 0.2-3.5 | 170 | 10 |

| NHS4 | 4 | 7.6 | 7 | 12 | 5.25 | 14 | M4X0.7 | 24 | 31 | 12 | 8 | 9.5 | 4 | 8 | 0.2-3.5 | 250 | 12 |

| NHS 5 | 5 | 7.7 | 8 | 12 | 6 | 16 | M5X0.8 | 27 | 35 | 14 | 9 | 12 | 4 | 9 | 0.2~3.5 | 800 | 16 |

| NHS6 | 6 | 9 | 9 | 10 | 6.75 | 18 | M6X1 | 30 | 39 | 14 | 10 | 13 | 5 | 11 | 0.2-3.5 | 880 | 25 |

| NHS 8 | 8 | 10.4 | 12 | 12 | 9 | 22 | M8X1.25 | 36 | 47 | 17 | 12.5 | 16 | 5 | 14 | 0.2-3.5 | 1200 | 43 |

| NHS 10 | 10 | 12.9 | 14 | 12 | 10.5 | 26 | M10x1.5 | 43 | 56 | 21 | 15 | 19 | 6.5 | 17 | 0.2-3.5 | 1700 | 72 |

| NHS 12 | 12 | 15.4 | 16 | 12 | 12 | 30 | M12x1.75 | 50 | 65 | 24 | 17.5 | 22 | 6.5 | 19 | 0.2~3.5 | 2400 | 107 |

| NHS 14 | 14 | 16.9 | 19 | 14 | 13.5 | 34 | M14X2 | 57 | 74 | 27 | 20 | 25 | 8 | 22 | 0.2-3.5 | 2700 | 160 |

| NHS 16 | 16 | 19.4 | 21 | 13 | 15 | 38 | M16X2 | 64 | 83 | 33 | 22 | 27 | 8 | 22 | 0.2-3.5 | 3400 | 210 |

| NHS 18 | 18 | 21.9 | 23 | 14 | 17 | 42 | M18X1.5 | 71 | 92 | 36 | 25 | 31 | 10 | 27 | 0.2-3.5 | 4700 | 295 |

| NHS 20 | 20 | 24.4 | 25 | 12 | 18 | 46 | M20x1.5 | 77 | 100 | 40 | 27.5 | 34 | 10 | 32 | 0.2-3.5 | 4900 | 380 |

Due to the self-aligning and low-friction characteristics of the joint bearings, NHS8T is mainly applicable to the following fields:

Automation equipment: mechanical arm joints, conveyor belt tensioning mechanisms;

Construction machinery: hydraulic cylinder piston rod connections, small actuator hinges;

Precision machine tools: feed mechanism fine adjustment joints, indexing plate connections;

Automotive industry: seat adjustment mechanisms, shock absorber connecting rods.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on