Item No :

PHS6 PHS6L rod end bearingSize (d*D*B) :

6x18x39x9mmMaterial :

steel with zinc platedLead Time :

normally 3-5 daysWeight :

0.0233KGMOQ :

100 PCSPHS6 PHS6L Female Thread Rod End Spherical Plain Bearing

⚙️Product Description:

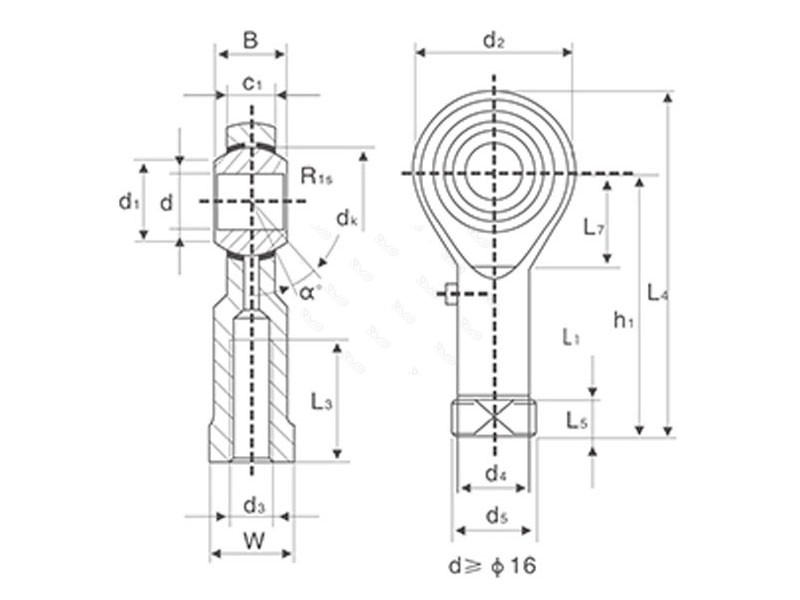

The PHS6 end joint bearing is a type of rod-end joint bearing with internal threads. It belongs to a special category of sliding bearings and is mainly used to achieve oscillation, rotation and angle compensation movements at low rotational speeds. The suffix "L" indicates left-handed threads (such as PHS6L), while no suffix indicates right-handed threads.

Structural features: This bearing is mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. The inner ring is typically made of bearing steel, such as GCR15 or AISI 52100, and after heat treatment, its hardness can reach HRC58-64. The outer ring is usually made of carbon steel, and its surface is treated with zinc plating and other processes to enhance its anti-corrosion performance. The sliding contact surface is a combination of steel and brass.

| Product name | PHS6 PHS6L rod end bearing |

| Size | 6x18x39x9mm |

| Material | steel with zinc plated |

| Weight | 0.0233KG |

| lead time | normally 3-5 days |

| Package | Single box +Carton +Pallet |

| MOQ | 100 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

Performance parameters: The basic rated dynamic load of the PHS6 bearing, Cd, is 4200N, and the basic rated static load, Cs, is 6910N. It has a certain load-bearing capacity and can withstand radial load, axial load, or the combined load of both.

Lubrication method: Some PHS6 bearings have lubrication holes and oil grooves, which can be lubricated through an oil nozzle to ensure that the sliding surfaces receive appropriate lubrication during use, thereby reducing wear and friction.

| Model No. | Main Dimension(mm) | Load (KN) | weight (g) | ||||||||||||||

| D | D3 | B | C1 | W | L3min | D2 | L4 | h1 | L5 | D4 | D5 | DK | D1 | Dyn.C | Stat.C0 | ||

| PHS 5 | 5 | M5*0.8 | 8 | 6 | 9 | 10 | 16 | 35 | 27 | 4 | 8.5 | 11 | 11.11 | 7.7 | 3.25 | 5.7 | 15.2 |

| PHS 6 | 6 | M6*1.0 | 9 | 6.75 | 11 | 12 | 18 | 39 | 30 | 5 | 10 | 13 | 12.7 | 8.96 | 4.3 | 7.2 | 22.3 |

| PHS 8 | 8 | M8*1.25 | 12 | 9 | 14 | 16 | 22 | 47 | 36 | 5 | 12.5 | 16 | 15.875 | 10.4 | 7.2 | 11.6 | 42.2 |

| PHS10 | 10 | M10*1.5 | 14 | 10.5 | 17 | 20 | 26 | 56 | 43 | 6.5 | 15 | 19 | 19.05 | 12.9 | 10 | 14.5 | 68.6 |

| PHS10-1 | 10 | M10'1.25 | 14 | 10.5 | 17 | 20 | 26 | 56 | 43 | 6.5 | 15 | 19 | 19.05 | 12.9 | 10 | 14.5 | 68.6 |

| PHS12 | 12 | M12*1.75 | 16 | 12 | 19 | 22 | 30 | 65 | 50 | 6.5 | 17.5 | 22 | 22.225 | 15.4 | 13.4 | 17 | 104 |

| PHS12-1 | 12 | M12-1.25 | 16 | 12 | 19 | 22 | 30 | 65 | 50 | 6.5 | 17.5 | 22 | 22.225 | 15.4 | 13.4 | 17 | 104 |

| PHS14 | 14 | M14*2.0 | 19 | 13.5 | 22 | 25 | 34 | 74 | 57 | 8 | 20 | 25 | 25.4 | 16.9 | 17 | 24 | 143.5 |

| PHS14-1 | 14 | M14*1.5 | 19 | 13.5 | 22 | 25 | 34 | 74 | 57 | 8 | 20 | 25 | 25.4 | 16.9 | 17 | 24 | 143.5 |

| PHS16 | 16 | M16*2.0 | 21 | 15 | 24 | 28 | 38 | 83 | 64 | 8 | 22 | 27 | 28.575 | 19.4 | 21.6 | 28.5 | 197.5 |

| PHS16-1 | 16 | M16*1.5 | 21 | 15 | 24 | 28 | 38 | 83 | 64 | 8 | 22 | 27 | 28.575 | 19.4 | 21.6 | 28.5 | 197.5 |

Widely used in various mechanical equipment such as crimping machines, hot pressing machines, gluing machines, vibration tables, electroplating equipment, etc. It is also commonly used in robot arms, packaging machinery, textile equipment, agricultural machinery, etc. It can operate normally under low-speed swinging, tilting motion and other working conditions.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on