Item No :

SA8T/K SAL8T/KSize (d*D*B) :

8x24x54x12mmMaterial :

steel/PTFE with zinc platedLead Time :

normally 3-5 daysWeight :

0.034KGMOQ :

50 PCSSA8T/K Self-lubricating Male Thread Rod End Bearing

⚙️Product description:

The SA8T/K rod-end ball bearing is a type of sliding bearing and is commonly used in mechanical components that require oscillating or tilting movements.

Structural features: The SA8T/K joint bearing is mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. This special structure enables it to perform inclined movement within a certain angle range and also adapt to situations where the eccentricity between the supporting shaft and the shaft housing hole is relatively large.

| Product name | SA8T/K SAL8T/K rod end bearing |

| Size | 8x24x54x12mm |

| Material | steel/PTFE with zinc plated |

| Weight | 0.034KG |

| lead time | normally 3-5 days |

| Package | single box +Carton +Pallet |

| MOQ | 50 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

Material composition: Generally, the ball is made of GCr15 chromium steel, which undergoes heat treatment and hard chrome plating; the liner is made of PTFE material; the outer ring is made of copper alloy; the main body is made of low-carbon steel, which undergoes heat treatment and nickel plating.

Performance features: Due to the large sliding contact area of the spherical shape, the large inclination angle, and the composite material embedded on the outer surface of the inner ring and the outer ball, this bearing has self-lubrication properties and can operate normally without lubricating grease contamination. It also has a large load-bearing capacity and impact resistance.

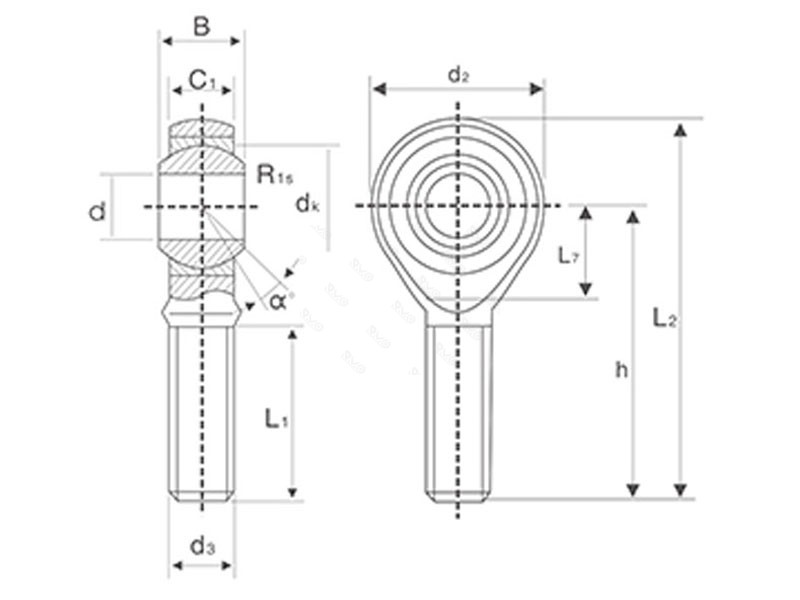

| Model No. | MAIN DIMENSIONS (mm) | Basic Loading | Weight(kg) | |||||||||||

| d | d3 | B | C1 max | L1 min | d2 max | L7 min | h | L2 max | dk | a' ≈ | Dynamic C(kgf) | Static Co(kgf) | ||

| SA3T/K | 3 | M3x0.5 | 6 | 4.5 | 15 | 12 | - | 27 | 33 | - | - | 1.8 | 3.528 | 0.006 |

| SA4T/K | 4 | M4x0.7 | 7 | 5.3 | 17 | 14 | - | 30 | 37 | - | - | 3.24 | 4.9 | 0.009 |

| SA5T/K | 5 | M5x0.8 | 8 | 6 | 19 | 18 | - | 33 | 42 | 11.11 | 13 | 3.25 | 3.1 | 0.013 |

| SA6T/K | 6 | M6x1 | 9 | 6.75 | 21 | 20 | - | 36 | 46 | 12.7 | 13 | 4.3 | 4.4 | 0.02 |

| SA8T/K | 8 | M8x1.25 | 12 | 9 | 25 | 24 | - | 42 | 54 | 15.875 | 14 | 7.2 | 8 | 0.034 |

| SA10T/K | 10 | M10x1.5 | 14 | 10.5 | 28 | 28 | - | 48 | 62 | 19.05 | 13 | 10 | 12.9 | 0.058 |

| SA12T/K | 12 | M12x1.75 | 16 | 12 | 32 | 32 | - | 54 | 70 | 22.225 | 13 | 13.4 | 17 | 0.092 |

| SA14T/K | 14 | M14x2 | 19 | 13.5 | 36 | 36 | 18 | 60 | 78 | 25.4 | 16 | 17 | 24 | 0.153 |

| SA16T/K | 16 | M16x2 | 21 | 15 | 37 | 40 | 23 | 66 | 86 | 28.575 | 15 | 21.6 | 28.5 | 0.205 |

| SA18T/K | 18 | M18x1.5 | 23 | 16.5 | 41 | 44 | 25 | 72 | 95 | 31.75 | 15 | 26 | 42.5 | 0.28 |

| SA20T/K | 20 | M20x1.5 | 25 | 18 | 45 | 48 | 26 | 78 | 102 | 34.925 | 14 | 31.5 | 42.5 | 0.37 |

| SA22T/K | 22 | M22x1.5 | 28 | 20 | 48 | 54 | 29 | 84 | 111 | 38.1 | 15 | 38 | 57 | 0.475 |

| SA25T/K | 25 | M24x2 | 31 | 22 | 55 | 60 | 32 | 94 | 124 | 42.85 | 15 | 47.5 | 68 | 0.65 |

| SA28T/K | 28 | M27x2 | 35 | 24 | 62 | 66 | 34 | 103 | 136 | 47.6 | 15 | 55 | 75.5 | 0.8 |

| SA30T/K | 80 | M30x2 | 37 | 25 | 66 | 70 | 37 | 110 | 145 | 50.8 | 17 | 64 | 88 | 1.07 |

It's widely used in engineering hydraulic cylinders, forging machines, construction machinery, automation equipment, automotive shock absorbers, water conservancy machinery, etc. It can be applied to the ends of control rods, steering connecting rods, tie rods, etc., to achieve precise hinge connections.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on