Item No :

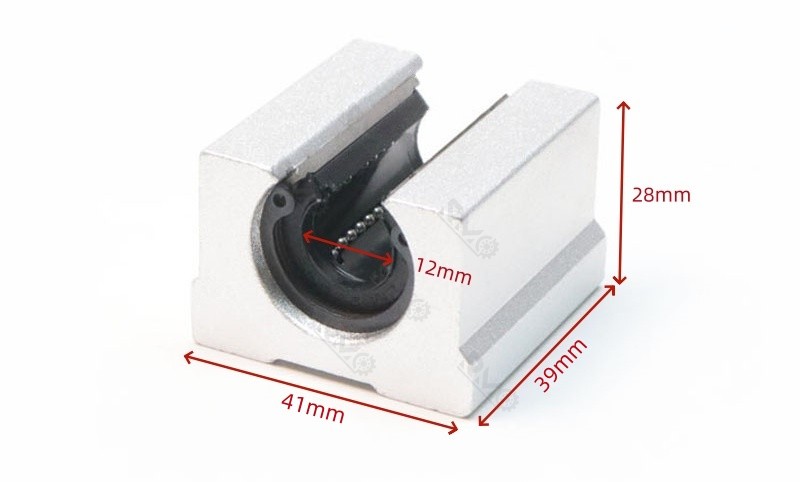

SBR12UU slide bearingSize (d*D*B) :

12x41x39x28mm (ID*W*L*F)Material :

chrome steel with aluminiumLead Time :

Normally 3-5 daysWeight :

0.1KGPayment Terms :

100% T/T or 30% T/T in advance ,70% before deliveryShipping Port :

Guangzhou, Ningbo, ShanghaiSBR12UU linear guide slider

⚙️Product description:

Inner diameter: 12mm, which means the shaft diameter that this slider is compatible with is 12mm.

Overall dimensions: Length 39mm, width 41mm, height 28mm. Products produced by different manufacturers may have slight differences in size.

Bearing material: Usually made of high-quality bearing steel, with chrome plating treatment on the surface, featuring high hardness and wear resistance, which can ensure the service life and motion accuracy of the slider.

Shell material: Made of aluminum alloy, with advantages of light weight, high strength, and corrosion resistance, making the slider both sturdy and durable, and easy to install and disassemble.

⚙️Product Advantages:

High precision: The positioning accuracy is high, capable of meeting various requirements for precise linear motion.

Low friction: The internal structure adopts a rolling bearing design, with a low friction coefficient, ensuring smooth movement and significantly reducing the power required for driving. At the same time, it reduces wear and maintains accuracy for a long time.

Low noise: During movement, the noise is relatively low, making it suitable for equipment with noise requirements for the working environment.

Strong load-bearing capacity: It can withstand loads from above and other directions, featuring high rigidity and stability.

Installation is convenient: Just align the interface between the slider and the guide rail, then gently push the slider to make it fall completely into the guide rail. Installation is completed without the need for complex debugging processes.

Maintenance is simple: Due to its structural design and material characteristics, this slider does not require frequent maintenance under normal use, reducing usage costs and maintenance workload.

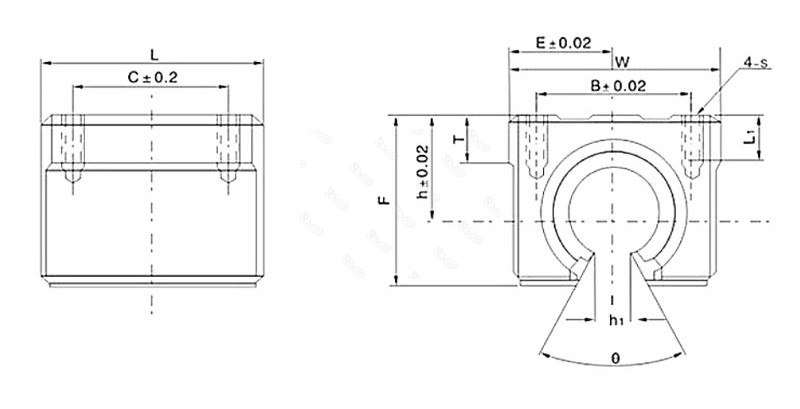

| Model No. | h | E | W | L | F | h1 | 0 | B | C | S | L1 | T | m | Load / dynamic | Load / Static |

| SBR10UU | 15 | 18 | 36 | 32 | 24 | 6 | 80° | 25 | 20 | M5 | 10 | 7 | 65 | 372 | 549 |

| SBR12UU | 17.5 | 20.5 | 41 | 39 | 28 | 7.5 | 80° | 28 | 26 | M5 | 10 | 8 | 100 | 420 | 610 |

| SBR16UU | 20 | 22.5 | 45 | 45 | 33 | 10 | 80° | 32 | 30 | M5 | 12 | 9 | 150 | 774 | 1180 |

| SBR20UU | 23 | 24 | 48 | 50 | 39 | 10 | 60° | 35 | 35 | M6 | 12 | 11 | 200 | 882 | 1370 |

| SBR25UU | 7 | 30 | 60 | 65 | 47 | 11.5 | 50° | 40 | 40 | M6 | 12 | 14 | 450 | 980 | 1570 |

| SBR30UU | 33 | 35 | 70 | 70 | 56 | 14 | 50° | 50 | 50 | M8 | 18 | 15 | 630 | 1570 | 2740 |

| SBR35UU | 37 | 40 | 80 | 80 | 63 | 16 | 50° | 55 | 55 | M8 | 18 | 18 | 925 | 1670 | 3140 |

| SBR40UU | 42 | 45 | 90 | 90 | 72 | 19 | 50° | 65 | 65 | M10 | 20 | 20 | 1330 | 2160 | 4020 |

| SBR50UU | 53 | 60 | 120 | 110 | 92 | 23 | 50° | 94 | 80 | M10 | 20 | 25 | 3000 | 3820 | 7940 |

Automated machinery: such as DIY CNC routers, lathes, milling machines, grinding machines, etc., used to achieve linear movement of worktables or cutting tools.

Industrial equipment: in equipment like stamping machines, automatic cutting machines, food packaging machines, card sorting machines, etc., as a guiding component for linear movement, ensuring the precise operation of the equipment.

Other fields: It can also be applied to large transmission equipment such as industrial robots, laser welding machines, bending machines, as well as some instruments and equipment with high requirements for the accuracy and stability of linear movement.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on