SFU1204 is a type of ball screw that is widely used in the field of precision machinery.

Item No :

SFU1204-L215.5mmSize (d*D*B) :

diameter: 12mm, lead: 4mm, length: 215.5mmMaterial :

Screw S55C, nut 20CrMoPrecision :

C7Lead Time :

Normally 5-7 daysSFU Series CNC Machine Parts SFU1204 Ball Screw

⚙️Product description:

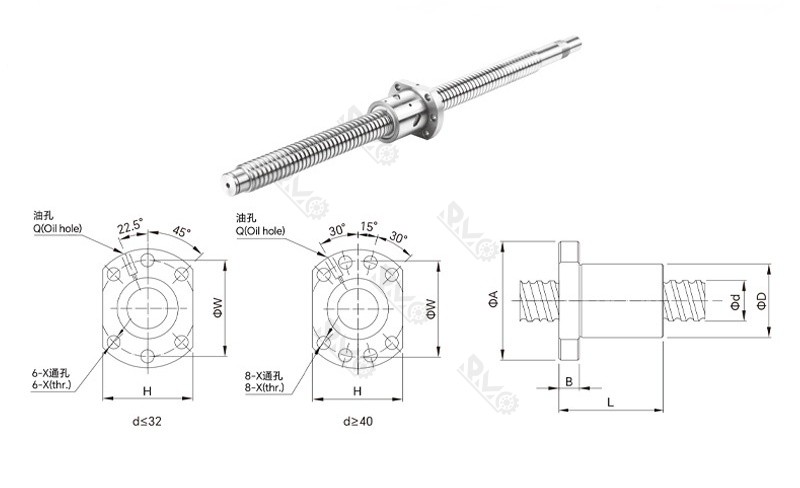

Specification parameters: "SFU" is the model identifier of the ball screw, "12" indicates that the outer diameter of the screw is 12mm. Its lead is 4mm, and the diameter of the balls is 2.381mm. In addition, there are different length specifications available for selection, such as SFU1204-1000L, which indicates that the length of the screw is 1000mm.

⚙️Structural composition:

It is composed of a screw, a nut and balls. The screw is machined with a linear ball guide rail, and the nut is equipped with corresponding balls. The movement is transmitted through the rolling of the balls between the screw and the nut.

⚙️Product features:

High precision: Utilizing high-precision processing techniques and strict quality control, it can provide high axial positioning accuracy and motion accuracy.

High rigidity: Exhibiting excellent axial and radial rigidity, it can withstand large loads without deformation, ensuring the stability and reliability of the transmission system.

High efficiency: Through the rolling friction of balls to transmit power, the friction coefficient is small, and the transmission efficiency is high, which can efficiently convert the rotational motion of the motor into linear motion, helping to improve equipment efficiency and reduce energy consumption.

Long service life: Under normal usage conditions, with appropriate lubrication and maintenance, it has a long service life, reducing the maintenance and replacement costs of the equipment.

⚙️Precision tolerance: C10, C7, C5, C3, -- The smaller the number, the higher the precision.

| Model No. | ID | Screw Lead I | (ball) Da |

Nut Dimension |

Load Rating | Rigidity | Weight | |||||||||

| D | A | B | L | W | H | X | Q | N | Co | Coa | Kg/um | Kg | ||||

| SFU1204-3 | 12 | 4 | 2.381 | 22/24 | 42 | 8 | 35 | 32 | 30 | 4.5 | M6 | 1x3 | 902 | 1884 | 26 | 0.138 |

| SPU1604-4 | 16 | 4 | 2.381 | 28 | 48 | 10 | 40 | 38 | 40 | 5.5 | M6 | 1x4 | 973 | 2406 | 32 | 0.184 |

| SPU1606-3/4 | 5 | 3.175 | 28 | 48 | 10 | 42/50 | 38 | 40 | 5.5 | M6 | 1x3/4 | 1380 | 3052 | 32 | 0.19 | |

| SPU1610-2/3 | 10 | 3.175 | 28 | 48 | 10 | 44/57 | 38 | 40 | 5.5 | M6 | 1x2/3 | 1103 | 2401 | 26 | 0.22 | |

| SFU2004-4 | 20 | 4 | 2.381 | 36 | 58 | 10 | 42 | 47 | 44 | 6.6 | M6 | 1x4 | 1066 | 2987 | 38 | 0.294 |

| SFU2005-3/4 | 5 | 3.175 | 36 | 58 | 19 | 44/51 | 47 | 44 | 6.6 | M6 | 1x3/4 | 1551 | 3875 | 38 | 0.316 | |

| SFU2010-2/3 | 10 | 3.175 | 36 | 58 | 10 | 44/60 | 47 | 44 | 6.6 | M6 | 1x4/3 | 1551 | 3875 | 38 | 032 | |

| SFU2504-4 | 25 | 4 | 2.381 | 40 | 62 | 10 | 42 | 51 | 48 | 6.6 | M6 | 1x4 | 1180 | 3795 | 43 | 0.384 |

| SFU2505-3/4 | 5 | 3.175 | 40 | 62 | 10 | 44/51 | 51 | 48 | 6.6 | M6 | 1x3/4 | 1724 | 4904 | 45 | 0.35 | |

| SFU2510-3/4 | 10 | 4.762 | 40 | 62 | 12 | 70/85 | 51 | 48 | 6.6 | M6 | 1x3/4 | 2954 | 7295 | 50 | 0.484 | |

| SFU3204-4 | 32 | 4 | 2.381 | 50 | 80 | 12 | 44 | 65 | 62 | 9 | M6 | 1x4 | 1296 | 4838 | 51 | 0.658 |

| SFU3205-4 | 5 | 3.175 | 50 | 80 | 12 | 52 | 65 | 62 | 9 | M6 | 1x4 | 1922 | 6343 | 54 | 0.588 | |

| SPU3210-3/4 | 10 | 6.35 | 50 | 80 | 12 | 74/90 | 65 | 62 | 9 | M6 | 1x3/4 | 4305 | 12208 | 61 | 0.832 | |

| SFU4005-3/4 | 40 | 5 | 3.175 | 63 | 93 | 14 | 45/55 | 78 | 70 | 9 | M8 | 1x4 | 2110 | 7988 | 63 | 0.97 |

| SFU4010-3/4 | 10 | 6.35 | 63 | 93 | 14 | 74/90 | 78 | 70 | 9 | M8 | 1x3/4 | 5399 | 15500 | 73 | 1.246 | |

| SFU5005-4 | 50 | 5 | 3.175 | 75 | 110 | 16 | 55 | 93 | 85 | 11 | M8 | 1x4 | 6004 | 19614 | 85 | 1.82 |

| SFU5010-4 | 10 | 6.35 | 75 | 110 | 16 | 93 | 93 | 85 | 11 | M8 | 1x4 | 6004 | 19614 | 85 | 1.82 | |

| SFU5020-4 | 20 | 7.144 | 75 | 110 | 16 | 138 | 93 | 85 | 11 | M8 | 1x4 | 7142 | 22588 | 94 | 2.674 | |

Widely applied in fields such as automated equipment, CNC machines, and medical devices. In automated production lines, it can be used for precise control of material transportation; in CNC machines, it can achieve high-precision processing of workpieces; in medical devices, it can be used for precise positioning and movement.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on