Item No :

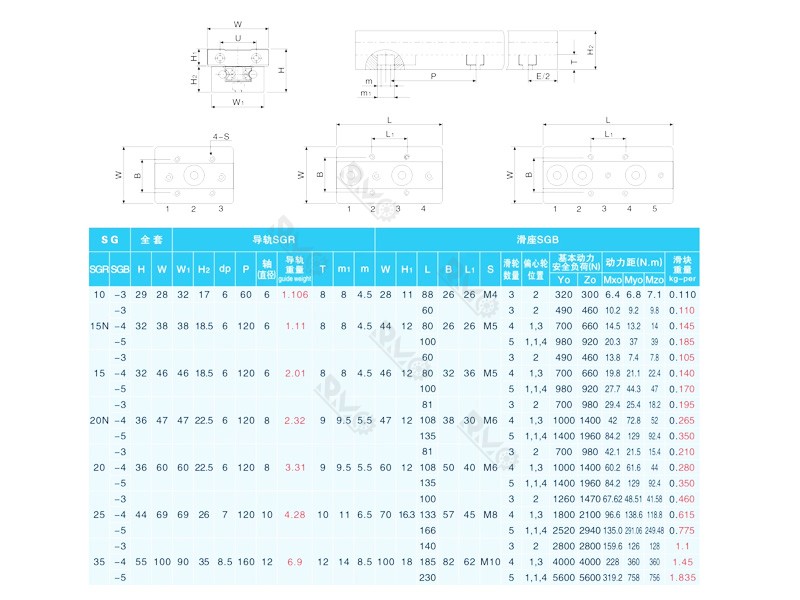

SGR10-3 Guide Slide BlockSize (d*D*B) :

60x32x29mmMaterial :

chrome steel with aluminiumLead Time :

Normally 3-5 daysWeight :

0.088KGMOQ :

50 pcsShipping Port :

Guangzhou, Ningbo, ShanghaiSGR10-3 Double-axis Core Guide Slide Block

⚙️Product description:

Basic structure: SGB10-3 roller slider often used in conjunction with SGR10 dual-axis guide rail. It consists of a slider body and three rollers. The slider body is generally made of aluminum alloy or other high-strength materials and is treated with oxidation to have good wear resistance and corrosion resistance. The rollers are made of high-quality materials such as bearing steel, ensuring the motion accuracy and stability of the slider.

⚙️Performance Features:

High Precision: Utilizing high-precision bearings, it ensures high positioning accuracy and repeatability during the movement of the slider.

High Speed: With low friction resistance, it can achieve a high running speed and operates smoothly with low noise.

Dust-proof Design: The slider usually has a certain dust-proof structure, suitable for use in harsh working environments with high dust content and severe pollution.

Easy Adjustment: By adjusting the eccentric position of the roller, the gap between the slider and the guide rail can be conveniently adjusted to achieve a "zero" gap standard, enhancing the rigidity and stability of the system.

⚙️Product Application:

It is widely used in various types of mechanical equipment that require linear motion, such as laser cutting machines, automatic dispensing machines, plastic machinery, printing machinery, textile machinery, semiconductor machinery, and medical equipment.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on