Item No :

ST16Size (d*D*B) :

16x28x37mmMaterial :

Chrome steel Gcr15Lead Time :

Normally 3-5 daysWeight :

0.085KGPayment Terms :

100% T/T or 30% T/T in advance ,70% before deliveryShipping Port :

Guangzhou, Ningbo, ShanghaiST16 Linear Stroke Bushing for 16mm Shaft

⚙️Product Description:

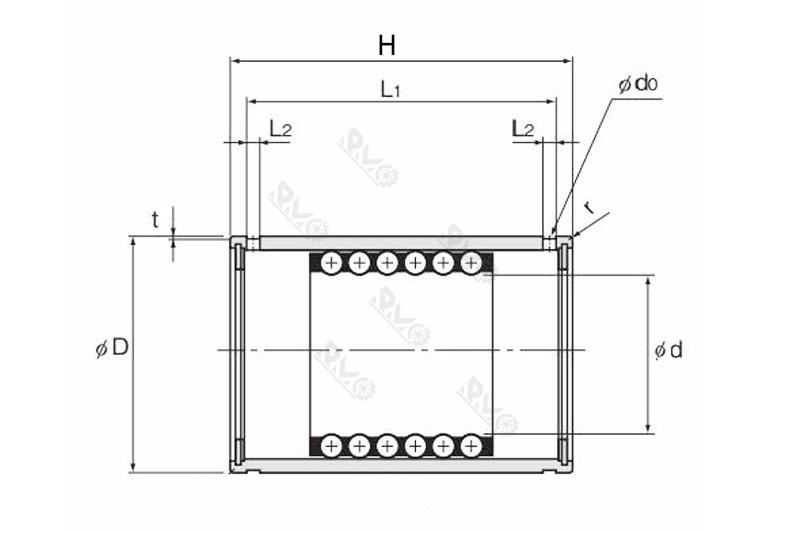

The ST16 Linear Stroke Bushing is designed for 16mm linear shafts to support smooth and stable travel movement in linear motion systems. It offers reliable guidance, low friction, and high durability, ensuring efficient operation in CNC machinery, automation equipment, and industrial motion platforms.

⚙️Technical Parameters:

|

Item No. |

ST16 |

|

Branding |

Famous brand/RMO/Neutral/OEM |

|

Sealing |

Open |

|

Material |

Chrome steel Gcr15 |

|

Lead Time |

3-5 days |

|

Precision |

P0 |

| Motion Type | Linear Stroke |

|

Structure Type |

Standard (Non‑Split) |

|

Shaft Diameter |

16mm |

|

Shipping Port |

Guangzhou, Ningbo, Shanghai |

|

Payment |

100% T/T, or 30% T/T In Advance ,70% T/T After Finished Production |

⚙️Product Features & Advantages:

• Smooth linear travel

• Low friction running

• Strong shaft guiding performance

• Durable housing material

• Suitable for continuous stroke motion

• Excellent stability during long movement

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| ST6 | 6 mm | 12 mm | 19 mm | 8 g | ST40B | 40 mm | 60 mm | 80 mm | 635 g | |

| ST8 | 8 mm | 15 mm | 24 mm | 16.4 g | ST45 | 45 mm | 65 mm | 80 mm | 625 g | |

| ST8B | 8 mm | 15 mm | 24 mm | 17.6 g | ST45B | 45 mm | 65 mm | 80 mm | 695 g | |

| ST10 | 10 mm | 19 mm | 30 mm | 31.5 g | ST50 | 50 mm | 72 mm | 100 mm | 910 g | |

| ST10B | 10 mm | 19 mm | 30 mm | 34.5 g | ST50B | 50 mm | 72 mm | 100 mm | 1020 g | |

| ST12 | 12 mm | 23 mm | 32 mm | 47 g | ST55 | 55 mm | 80 mm | 100 mm | 1270 g | |

| ST12B | 12 mm | 23 mm | 32 mm | 53.5 g | ST55B | 55 mm | 80 mm | 100 mm | 1380 g | |

| ST16 | 16 mm | 28 mm | 37 mm | 77 g | ST60 | 60 mm | 85 mm | 100 mm | 1360 g | |

| ST16B | 16 mm | 28 mm | 37 mm | 85 g | ST60B | 60 mm | 85 mm | 100 mm | 1480 g | |

| ST20 | 20 mm | 32 mm | 45 mm | 109 g | ST70 | 70 mm | 95 mm | 100 mm | 1530 g | |

| ST20B | 20 mm | 32 mm | 45 mm | 120 g | ST70B | 70 mm | 95 mm | 100 mm | 1670 g | |

| ST25 | 25 mm | 37 mm | 45 mm | 128 g | ST80 | 80 mm | 110 mm | 100 mm | 2220 g | |

| ST25B | 25 mm | 37 mm | 45 mm | 142 g | ST80B | 80 mm | 110 mm | 100 mm | 2430 g | |

| ST30 | 30 mm | 45 mm | 65 mm | 240 g | ST90 | 90 mm | 120 mm | 100 mm | 2440 g | |

| ST30B | 30 mm | 45 mm | 65 mm | 275 g | ST90B | 90 mm | 120 mm | 100 mm | 2670 g | |

| ST35 | 35 mm | 52 mm | 70 mm | 370 g | ST100 | 100 mm | 130 mm | 100 mm | 2670 g | |

| ST35B | 35 mm | 52 mm | 70 mm | 410 g | ST100B | 100 mm | 130 mm | 100 mm | 2910 g | |

| ST40 | 40 mm | 60 mm | 80 mm | 570 g | ST100B | 100 mm | 130 mm | 100 mm | 2910 g |

• CNC machining equipment

• Industrial automation

• Linear stroke systems

• Packaging equipment

• Printing machinery

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on