This is a bearing housing made of ductile iron, featuring high strength, good toughness and excellent wear resistance.

Item No :

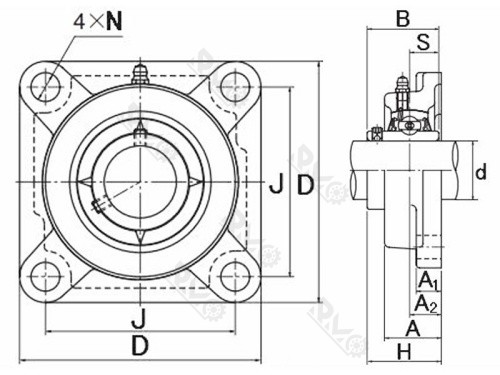

UCF210Size (d*D*B) :

50x143x54.6mmLead Time :

3-5 daysWeight :

2.5KGShipping Port :

GuangZhou, NingBo, ShangHaiMOQ :

50pcsUCF210 Ductile Iron Square Pillow Block Bearing

⚙️Component composition:

Outer spherical bearing: The outer diameter of the rolling bearing is usually made in a spherical shape. Its internal structure can be the same as that of the 6200 and 6300 series deep groove ball bearings, and it can withstand radial loads and certain axial loads.

Bearing housing: Generally, it is cast. Common housings include vertical housing (P), square housing (F), raised square housing (FS), raised circular housing (FC), rhombic housing (FL), circular housing (C), and slider housing (T), etc.

The carbon content of ductile iron (QT450) is controlled within 3.6% to 3.9%, and the silicon content is 2.0% to 2.8%. Alloying elements such as magnesium and calcium are added to make the graphite in the material spherical, significantly enhancing the mechanical properties of the material. Compared with gray cast iron (HT200), ductile iron outperforms in terms of rigidity, impact resistance and corrosion resistance.

⚙️Performance features:

Automatic centering function: The outer diameter of the bearing and the inner diameter of the bearing seat adopt a spherical fitting method, which can effectively compensate for the errors such as non-coincidence of the axis due to installation and deformation of the installation base.

Large load capacity: The internal structure is the same as that of the 6200 and 6300 series deep groove ball bearings, capable of withstanding large radial loads and certain axial loads, and having low working noise.

Long service life: It can operate in harsh environments such as soil, dust, humidity and high temperatures, but lubricating grease needs to be replaced in time to ensure appropriate lubrication intervals and lubrication volume.

Excellent sealing performance: Usually, it is equipped with a combined sealing device consisting of heat-resistant, oil-resistant rubber sealing rings and steel plate dust-proof covers, which effectively prevents foreign objects from entering while also resisting external deformation pressure.

Compact structure, convenient installation: The integrated design reduces the installation steps and lowers the requirements for installation accuracy, suitable for situations with limited space or for quick replacement of bearings.

Easy maintenance: Some models are designed with sealing devices, effectively preventing dust and moisture from entering, prolonging the service life of the bearing, and facilitating lubrication and inspection through the oil ports on the bearing seat.

⚙️Classification:

By the clamping method of the bearing and the shaft: with cotter pins, with eccentric sleeves, with locking sleeves in conical holes, and locking sleeves.

By the material of the bearing housing: usually there are two types: cast housings and stamped housings.

| Model No. | d | D | H | m |

| UCF201 | 12 mm | 86 mm | 33.3 mm | 0.6 KG |

| UCF202 | 15 mm | 86 mm | 33.3 mm | 0.6 KG |

| UCF203 | 17 mm | 86 mm | 33.3 mm | 0.6 KG |

| UCF204 | 20 mm | 86 mm | 33.3 mm | 0.6 KG |

| UCF205 | 25 mm | 95 mm | 35.8 mm | 0.8 KG |

| UCF206 | 30 mm | 108 mm | 40.2 mm | 1.1 KG |

| UCF207 | 35 mm | 117 mm | 44.4 mm | 1.5 KG |

| UCF208 | 40 mm | 130 mm | 51.2 mm | 1.7 KG |

| UCF209 | 45 mm | 137 mm | 52.2 mm | 2.1 KG |

| UCF210 | 50 mm | 143 mm | 54.6 mm | 2.5 KG |

| UCF211 | 55mm | 162 mm | 58.4 mm | 3.3 KG |

| UCF212 | 60 mm | 175 mm | 68.7 mm | 3.9 KG |

| UCF213 | 65 mm | 187 mm | 69.7 mm | 5.5 KG |

| UCF214 | 70 mm | 193 mm | 75.4 mm | 6.3 KG |

| UCF215 | 75 mm | 200 mm | 78.5 mm | 6.6 KG |

| UCF216 | 80 mm | 208 mm | 83.3 mm | 7.9 KG |

| UCF217 | 85 mm | 220 mm | 87.6 mm | 9.8 KG |

| UCF218 | 90 mm | 235 mm | 96.3 mm | 12 KG |

⚙️Application fields:

Widely used in various transmission devices and ordinary machinery, suitable for situations where installation space and the distance between shafts are limited. It is widely applied in fields such as metallurgical equipment, mining machinery, construction machinery, paper machinery, agricultural machinery, textile machinery, chemical machinery, and conveying machinery.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on